Up North Aviation

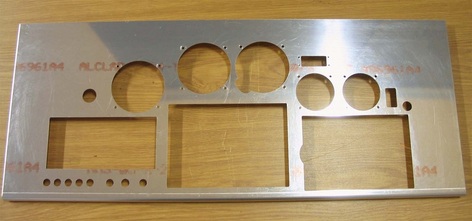

Alan C. RV-8 Panel Cut on 1/26/2011

"Bill was a pleasure to deal with, and does really first-rate work. He patiently worked through multiple iterations of my panel drawing (due to various small errors on my part), and created CAD drawing using the dimensions I supplied. I then had the panel blank shipping directly to him from Van's, which Bill cut and shipped to me within a day or so of his receiving it. The quality of the result was perfect so far as I can determine. I would gladly use him again."

"Bill was a pleasure to deal with, and does really first-rate work. He patiently worked through multiple iterations of my panel drawing (due to various small errors on my part), and created CAD drawing using the dimensions I supplied. I then had the panel blank shipping directly to him from Van's, which Bill cut and shipped to me within a day or so of his receiving it. The quality of the result was perfect so far as I can determine. I would gladly use him again."

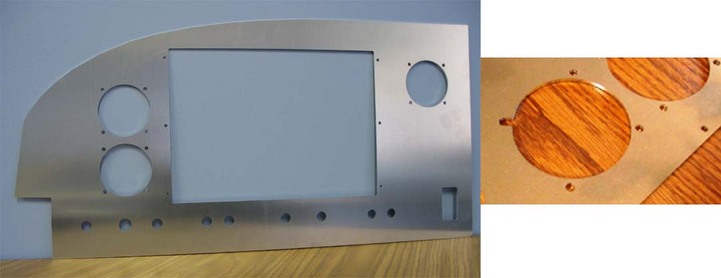

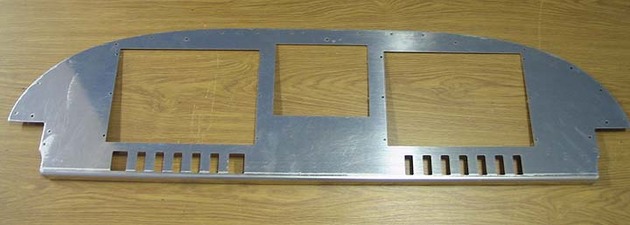

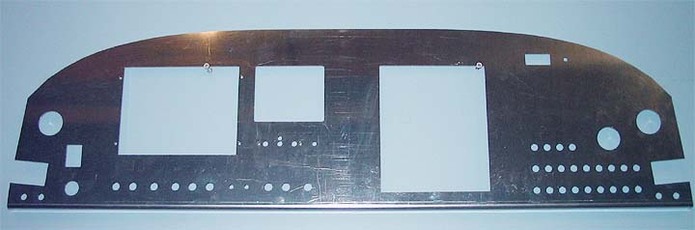

Gil A. RV-6 Left Side Panel Panel Cut on 1/27/2011

"Cut from a TurboCAD DWG file in 0.090 thinck 2024-T3 aluminum. The resulting panel is nicely cut and very accurate. Working from a computer file rather than manually cutting makes the square holes easier and much more accurate. The mounting for the 10 inch Dynon Skyview screen is accurate and is just a straight copy of dimensions from the data sheet. The close up picture shows the nice smooth, sharp edge on all of the holes and cutouts.

I did find that the "bezier" curve function in TurboCAD did not translate well, so the large curve at the top of the panel was manually made from a number of small straight lines, easy to do in TurboCAD.

Overall, a very nice job and a lot of time savings for a much better panel than I could have achieved with multiple cutting tools and files in my workshop."

"Cut from a TurboCAD DWG file in 0.090 thinck 2024-T3 aluminum. The resulting panel is nicely cut and very accurate. Working from a computer file rather than manually cutting makes the square holes easier and much more accurate. The mounting for the 10 inch Dynon Skyview screen is accurate and is just a straight copy of dimensions from the data sheet. The close up picture shows the nice smooth, sharp edge on all of the holes and cutouts.

I did find that the "bezier" curve function in TurboCAD did not translate well, so the large curve at the top of the panel was manually made from a number of small straight lines, easy to do in TurboCAD.

Overall, a very nice job and a lot of time savings for a much better panel than I could have achieved with multiple cutting tools and files in my workshop."

Joshua W. RV-9A Panel Cut on 2/14/2011

"I enjoyed working with Bill on my RV-9A panel. The process was easy and fast, and the communication clear, precise, and friendly. The panel turned out great and everything fits as expected with accurate placement of cutouts and holes. I wouldn't hesitate to recommend Bill to other builders, and I'll be a repeat customer if I update my panel in the future."

"I enjoyed working with Bill on my RV-9A panel. The process was easy and fast, and the communication clear, precise, and friendly. The panel turned out great and everything fits as expected with accurate placement of cutouts and holes. I wouldn't hesitate to recommend Bill to other builders, and I'll be a repeat customer if I update my panel in the future."

Carlos F. Rally Storm Panel Cut on 2/14/2011

"The panel turned out great! I cleaned up the corners, check the fit with the instruments and sent it to the powder coater. Thanks for the quick turnaround. This would have taken hours to cut by hand. I will be sending you more work if you want it. Again, thanks for the quick turnaround and excellent work. I would (did) recommend you to anyone looking to save time with their panel making. "

"The panel turned out great! I cleaned up the corners, check the fit with the instruments and sent it to the powder coater. Thanks for the quick turnaround. This would have taken hours to cut by hand. I will be sending you more work if you want it. Again, thanks for the quick turnaround and excellent work. I would (did) recommend you to anyone looking to save time with their panel making. "

Mike D. RV-7 Partial Panel Cut 2/24/11

"Bill was very professional in his approach as we worked toward updating my instrument panel. He took my ideas, offered his suggestions and produced a top notch final product. Every component fit into their respective cutouts as we had planned. His advise about thinking of the panel in 3 dimensions, where consideration of the “behind the panel” structure and installed items, was spot on. A minor measuring error on my part required that I do some minor reworking at the top to include all of the components. I’m very pleased with the final results and highly recommend Bill for those looking to design and produce a top quality instrument panel or update to their existing panel."

"Bill was very professional in his approach as we worked toward updating my instrument panel. He took my ideas, offered his suggestions and produced a top notch final product. Every component fit into their respective cutouts as we had planned. His advise about thinking of the panel in 3 dimensions, where consideration of the “behind the panel” structure and installed items, was spot on. A minor measuring error on my part required that I do some minor reworking at the top to include all of the components. I’m very pleased with the final results and highly recommend Bill for those looking to design and produce a top quality instrument panel or update to their existing panel."

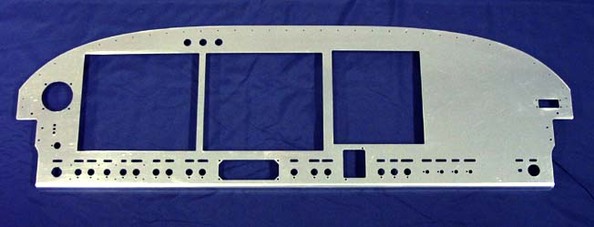

Doug P. RV-10 Panel Cut on 3/01/2011

"Bill I what to thank you for your excellent customer service and product knowledge. Your assistance identifying accurate cut dimensions prior to machining certainly was a relief knowing that all instrument and avionics would fit perfectly. Your prompt communication and turnaround time kept my panel build on schedule. The quality was stellar, you certainly have a very proficient understanding of CAD and machining processes. Again thank you for a pleasurable professional experience"

"Bill I what to thank you for your excellent customer service and product knowledge. Your assistance identifying accurate cut dimensions prior to machining certainly was a relief knowing that all instrument and avionics would fit perfectly. Your prompt communication and turnaround time kept my panel build on schedule. The quality was stellar, you certainly have a very proficient understanding of CAD and machining processes. Again thank you for a pleasurable professional experience"

Presley M. RV-8 Panel Cut on 3/08/2011

"Thanks for the good work in designing and cutting the new panel for my RV-8. You did a fine job of helping me incorporate most of my existing panel gauges while adding a Grand Rapids Sport with 8.4" screen. The finished product will look outstanding.

You did a good job of laying it out with your CAD program, particularly on the left side where there are some really tight clearances. There are some braces behind the panel of an RV-8 that must be worked around -- you handled it.

I liked being able to go to Kinkos and print out a full-size drawing to think about prior to you actually cutting the aluminum. The panel as you sent it requires a very minimum of dressing up prior to paint.

Thanks again. I would recommend your services to any other aircraft owner."

"Thanks for the good work in designing and cutting the new panel for my RV-8. You did a fine job of helping me incorporate most of my existing panel gauges while adding a Grand Rapids Sport with 8.4" screen. The finished product will look outstanding.

You did a good job of laying it out with your CAD program, particularly on the left side where there are some really tight clearances. There are some braces behind the panel of an RV-8 that must be worked around -- you handled it.

I liked being able to go to Kinkos and print out a full-size drawing to think about prior to you actually cutting the aluminum. The panel as you sent it requires a very minimum of dressing up prior to paint.

Thanks again. I would recommend your services to any other aircraft owner."

Tom M. RV-4 Panel Cut on 3/08/2011

"I want to thank you so much for your work and efforts to make my panel exactly as I wanted it. A panel for an RV-4 is rather complex as the panel real estate is very limited. Your efforts to communicate with me to be sure that we were planning for the exact components was appreciated. Thank you for questioning me to be sure we were using the correct intercom and other components, and where each item was to go. The results are perfect. I believe that the ability and ease to communicate with you and your ability to communicate with me is why I ended up with the results that I was looking for "

"I want to thank you so much for your work and efforts to make my panel exactly as I wanted it. A panel for an RV-4 is rather complex as the panel real estate is very limited. Your efforts to communicate with me to be sure that we were planning for the exact components was appreciated. Thank you for questioning me to be sure we were using the correct intercom and other components, and where each item was to go. The results are perfect. I believe that the ability and ease to communicate with you and your ability to communicate with me is why I ended up with the results that I was looking for "

Mark D. RV-8 Panel Cut on 3/14/2011

"I couldn't be happier with the panel layout you designed and cut for my RV-8A. I appreciate the time and effort you took to make all of my avionics fit properly. The quality of the workmanship is exceptional. Thanks again. I would highly recommend your services."

"I couldn't be happier with the panel layout you designed and cut for my RV-8A. I appreciate the time and effort you took to make all of my avionics fit properly. The quality of the workmanship is exceptional. Thanks again. I would highly recommend your services."

Larry S. RV-8 Panel Cut on 3/21/2011

"I recently engaged Mr. Morelli for help with the construction of the cutouts for my RV-8 center section instrument panel and could not have been more pleased. His suggestions during the layout phase were both timely and accurate. He discovered errors in my AutoCAD layout that were due to inaccuracies in the base drawing furnished by Van's (it's 1" longer in their drawing than in real life) and suggested that several radios be relocated due to possible interference issues with Z channel braces behind the panel. Either of these errors would have been major problems, and might not have been discovered until metal had been cut or installation started. A trial fit of the instruments into the finished product has been perfect and workmanship appears to be excellent. I'll use him again. Highly recommended."

"I recently engaged Mr. Morelli for help with the construction of the cutouts for my RV-8 center section instrument panel and could not have been more pleased. His suggestions during the layout phase were both timely and accurate. He discovered errors in my AutoCAD layout that were due to inaccuracies in the base drawing furnished by Van's (it's 1" longer in their drawing than in real life) and suggested that several radios be relocated due to possible interference issues with Z channel braces behind the panel. Either of these errors would have been major problems, and might not have been discovered until metal had been cut or installation started. A trial fit of the instruments into the finished product has been perfect and workmanship appears to be excellent. I'll use him again. Highly recommended."

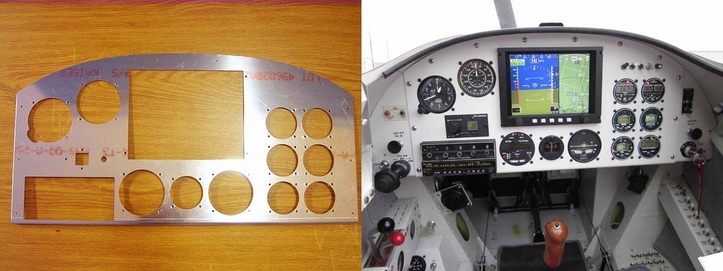

Rodney W. RV-4 Panel Cut on 4/05/2011

"To anyone out there looking to upgrade their panel, (who’s not, right) thought I’d share my recent experience with you. I ran across a blog from a William Morelli (“Bill”) who offered his services in a CNC cutout of a panel for my RV-4. I had recently purchased a Garmin 696 and wanted to update my panel while at the same time incorporating the 696 into it. I contacted Bill and he enthusiastically agreed to take on my project and am I glad he did.

I sent Bill a proposed panel layout that incorporated the instruments I want to keep and those I wanted to upgrade to. I also sent him a picture of the present panel so he could get an idea of what all he was working with. Bill obtained a CAD drawing of the RV-4 panel, researched the dimensions of the proposed new instruments going in the panel along with the pictures I had provided (to insure he was including everything on the panel that was being transferred from the old panel) and produced a CAD drawing which conclusively proved that without shrinking the instruments or expanding the panel, I wasn’t going to fit everything in the panel.

A little discouraged (me, not Bill) but undaunted, Bill and I kicked around a few ideas, traded the 696 for a 496, and came up with a panel which was perfect for me and my flying, that would fit in the RV-4 and allow me to reuse the instruments that weren’t outdated, replace the ones that were, in a layout that was extremely functional, simple and very ecstatically pleasing. Bill immediately sent me a “shrunk” version of the new CAD drawing as well as a “life size” version to make sure I was satisfied. Once I approved the panel layout, Bill CNC cut the panel and sent the finished version to me. It is awesome. I have attached a picture of Bill’s fine work as a testament. If anyone is thinking of putting in a new panel and you can talk Bill into helping you, I guarantee you he will save you a lot of time and brings a world of experience to panel design which could keep you from making some expensive mistakes like he did for me."

"To anyone out there looking to upgrade their panel, (who’s not, right) thought I’d share my recent experience with you. I ran across a blog from a William Morelli (“Bill”) who offered his services in a CNC cutout of a panel for my RV-4. I had recently purchased a Garmin 696 and wanted to update my panel while at the same time incorporating the 696 into it. I contacted Bill and he enthusiastically agreed to take on my project and am I glad he did.

I sent Bill a proposed panel layout that incorporated the instruments I want to keep and those I wanted to upgrade to. I also sent him a picture of the present panel so he could get an idea of what all he was working with. Bill obtained a CAD drawing of the RV-4 panel, researched the dimensions of the proposed new instruments going in the panel along with the pictures I had provided (to insure he was including everything on the panel that was being transferred from the old panel) and produced a CAD drawing which conclusively proved that without shrinking the instruments or expanding the panel, I wasn’t going to fit everything in the panel.

A little discouraged (me, not Bill) but undaunted, Bill and I kicked around a few ideas, traded the 696 for a 496, and came up with a panel which was perfect for me and my flying, that would fit in the RV-4 and allow me to reuse the instruments that weren’t outdated, replace the ones that were, in a layout that was extremely functional, simple and very ecstatically pleasing. Bill immediately sent me a “shrunk” version of the new CAD drawing as well as a “life size” version to make sure I was satisfied. Once I approved the panel layout, Bill CNC cut the panel and sent the finished version to me. It is awesome. I have attached a picture of Bill’s fine work as a testament. If anyone is thinking of putting in a new panel and you can talk Bill into helping you, I guarantee you he will save you a lot of time and brings a world of experience to panel design which could keep you from making some expensive mistakes like he did for me."

Gordon D. RV-7 Panel Cut on 4/20/2011

"What a pleasure it was to work with Bill. Since I had no experience in AutoCAD, Bill was willing to do the CAD drawing for me. All I did was send him a sketch of how I wanted my panel to look and a list of equipment that was being installed. I was extremely impressed with Bill’s attention to every detail. He researched the make and model of each piece of equipment and every switch and light to ensure the proper dimensions. Bill is an incredibly patient man and very easy to work with. He never seemed to mind any changes I had requested during the design process. Bill was always prompt on returning drawing revisions to me. He even checked on me from time to time if he hadn’t heard back from me concerning a revision. Now that’s what I call service. My panel turned out beautifully, just as I had hoped for. For anyone building an airplane, I highly recommend to let Bill cut your panel for you. You will have no regrets."

"What a pleasure it was to work with Bill. Since I had no experience in AutoCAD, Bill was willing to do the CAD drawing for me. All I did was send him a sketch of how I wanted my panel to look and a list of equipment that was being installed. I was extremely impressed with Bill’s attention to every detail. He researched the make and model of each piece of equipment and every switch and light to ensure the proper dimensions. Bill is an incredibly patient man and very easy to work with. He never seemed to mind any changes I had requested during the design process. Bill was always prompt on returning drawing revisions to me. He even checked on me from time to time if he hadn’t heard back from me concerning a revision. Now that’s what I call service. My panel turned out beautifully, just as I had hoped for. For anyone building an airplane, I highly recommend to let Bill cut your panel for you. You will have no regrets."

Robin H. RV-9 Panel Cut on 4/28/2011

"My panel design included fourteen rectangular holes for toggle switches. This was reason enough to take the CNC route compared to cutting by hand. Bill exchanged DXF files with me through some interactive changes until the design was finalized. I shipped the panel and Bill turned it around in 48 hours. The results were precise and exactly to the specification of the panel components. I wouldn't hesitate to use Bill's services in future."

"My panel design included fourteen rectangular holes for toggle switches. This was reason enough to take the CNC route compared to cutting by hand. Bill exchanged DXF files with me through some interactive changes until the design was finalized. I shipped the panel and Bill turned it around in 48 hours. The results were precise and exactly to the specification of the panel components. I wouldn't hesitate to use Bill's services in future."

Matt M. RV-4 Partial Panel Cut on 5/22/2011

"Bill was able to custom CAD and cut my panel overlay in no time. From ordering the blank material, to fine-tuning the design, and delivering the finished product, Bill walked me through each step and made it easy. Plus his prices can't be beat. I'd recommend him to anyone who's upgrading their panel."

"Bill was able to custom CAD and cut my panel overlay in no time. From ordering the blank material, to fine-tuning the design, and delivering the finished product, Bill walked me through each step and made it easy. Plus his prices can't be beat. I'd recommend him to anyone who's upgrading their panel."

Craig B. RV-6 Panel Cut on 6/24/2011

"I asked Up North Aviation to cut the panel for my RV6 and I cannot say enough about the patience, expertise, and professionalism displayed by Mr. Bill Morelli. I can't count the number of changes I requested - all of which were adopted in to my panel design accurately and promptly. In several cases, Bill was able to refine cut outs in the panel for me simply by providing him the make and model of the item to be installed. This saved me a lot of time. Trial fitting of my instruments in the panel confirmed that everything had been cut to the precise size and location requested.

Overall the process was extremely easy and I would not hesitate doing business with Up North Aviation again."

"I asked Up North Aviation to cut the panel for my RV6 and I cannot say enough about the patience, expertise, and professionalism displayed by Mr. Bill Morelli. I can't count the number of changes I requested - all of which were adopted in to my panel design accurately and promptly. In several cases, Bill was able to refine cut outs in the panel for me simply by providing him the make and model of the item to be installed. This saved me a lot of time. Trial fitting of my instruments in the panel confirmed that everything had been cut to the precise size and location requested.

Overall the process was extremely easy and I would not hesitate doing business with Up North Aviation again."

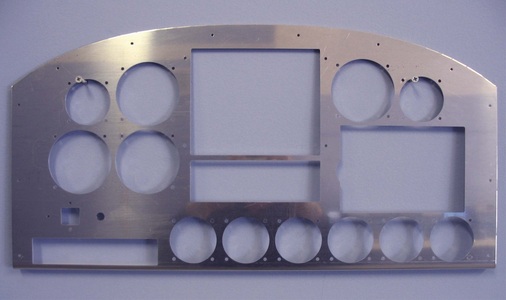

Clifford Coy - President, Border Air Ltd. IAR-823

Panel Cut on 8/19/2011

"Bill at Up North Aviation did an excellent job working with our specific needs.

His attention to detail and communication with our shop allowed us to provide our customers with an exact fit panel in less than a day."

Panel Cut on 8/19/2011

"Bill at Up North Aviation did an excellent job working with our specific needs.

His attention to detail and communication with our shop allowed us to provide our customers with an exact fit panel in less than a day."

Proudly powered by Weebly