Up North Aviation

While the PanelPro CNC system I use can cut and place cutouts with extreme accuracy, there are some cuts that it can't perform.

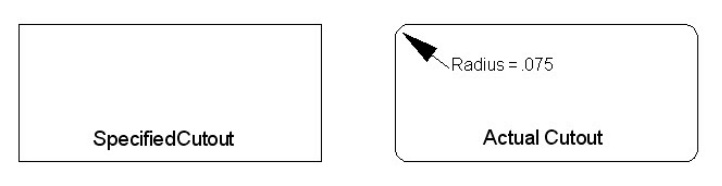

Square Inside Corners

- The PanelPro uses an End Mill (see above) to perform its cuts. Since end mills are round, when the system cuts an inside corner, it leaves a radius so the corner will not be square.

- These radius corners may need some slight filing with a small round file to fit a square unit in the cutout.

Looking on the bright side -- It is desirable to NOT use square inside corners on aircraft construction anyway. They are much more prone to stress cracks.

Square Inside Corners

- The PanelPro uses an End Mill (see above) to perform its cuts. Since end mills are round, when the system cuts an inside corner, it leaves a radius so the corner will not be square.

- These radius corners may need some slight filing with a small round file to fit a square unit in the cutout.

Looking on the bright side -- It is desirable to NOT use square inside corners on aircraft construction anyway. They are much more prone to stress cracks.

Proudly powered by Weebly